Why so many users choose Voiern laser

Voiern

Voiern  June 17,2025

June 17,2025

1.SIOS(System Integration Optimization System)

Our company uses SIOS system to collect the operating data of each system of the machine for processing and analysis, optimize the parts of the machine, and make the working of each component of the machine work optimally. The whole machine has higher working efficiency, which makes the machine run more stable, work more accurately, lower loss and longer service life. Compared with other machines that are not optimized with the SIOS system, even if the same machine configuration or system is used, we use the SIOS optimization system to make the machine run more smoothly, and the configuration or system life will be longer.

2. 8S management

The factory production workshop uses 8S management to effectively improve production efficiency and reduce the failure rate of the machine due to human factors, so as to achieve the goal of minimizing the loss caused by the failure rate.

3.Selected components

Even the screws of the fixed parts are selected from a number of suppliers in the market to select the best stainless steel screws for the fixed machine parts. Each type of screw used in each position of each machine is tested repeatedly to make the machine run more. Stable, improve machine life and reduce machine failure rate. So every component of the machine is a perfect piece of work.

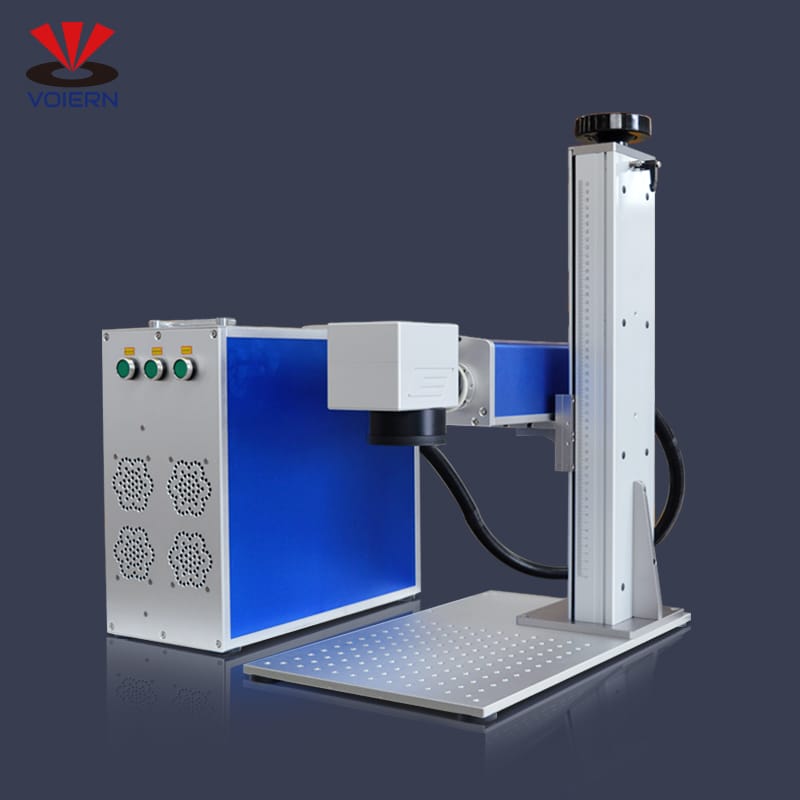

4.Housing of patented

The machine casing is made of more thicker steel plate, and the casing of the “balanced mechanics” integrated industrial design concept has been patented in the design of the machine. The parts of the casing frame are evenly stressed, which increases the stability of the machine and makes it work more smooth, so our machines have a longer service life than the other machines that have steel plates of the same thickness.