Star Laser Machine

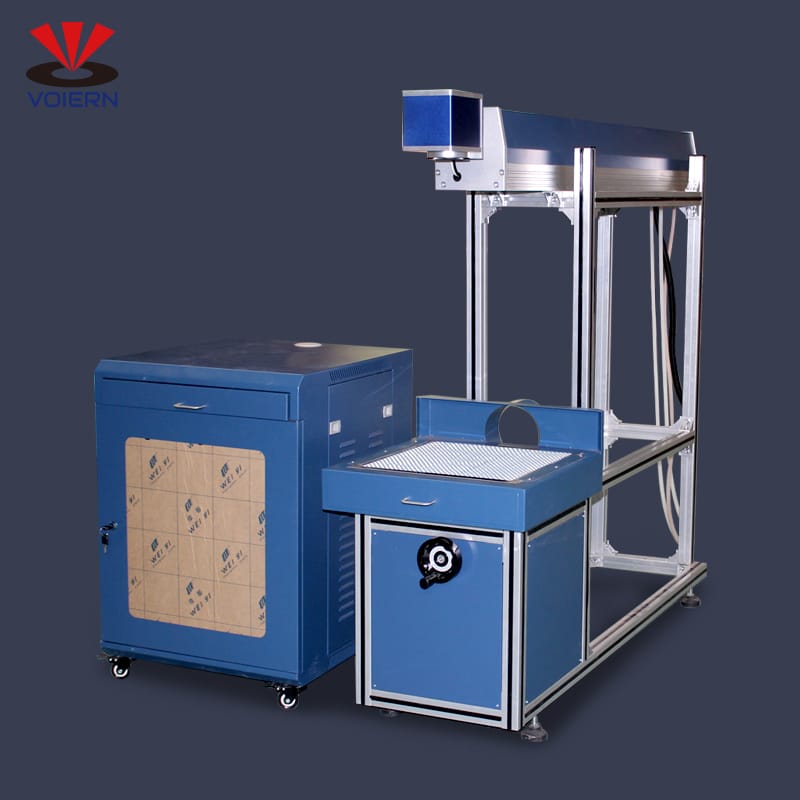

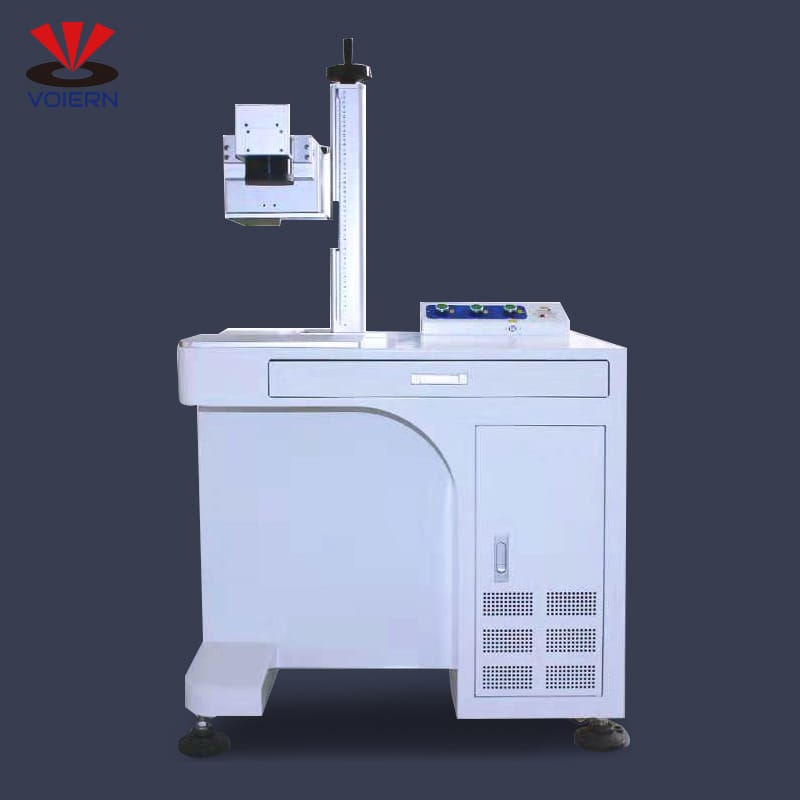

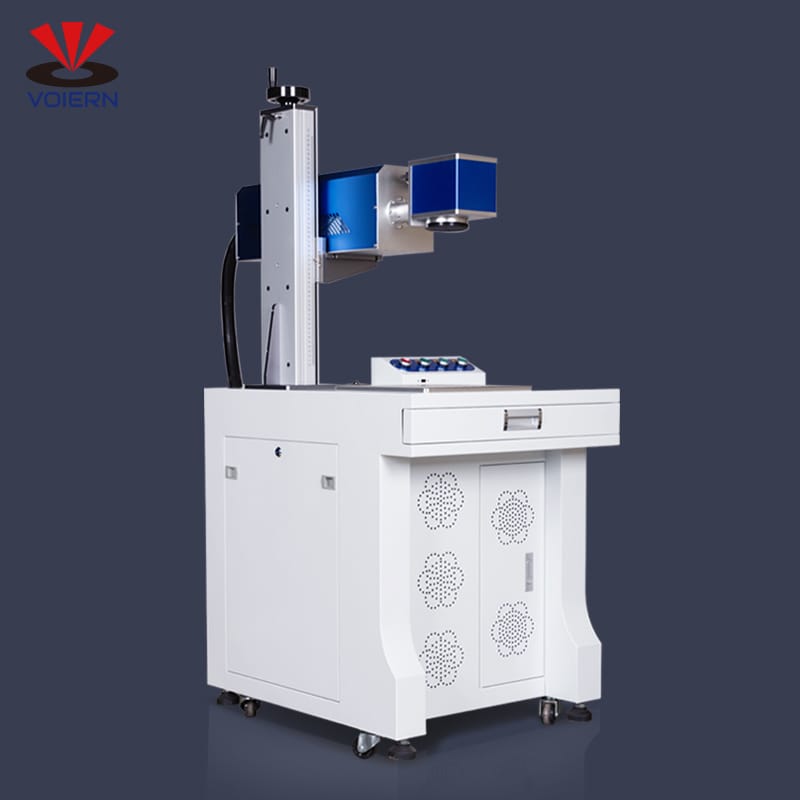

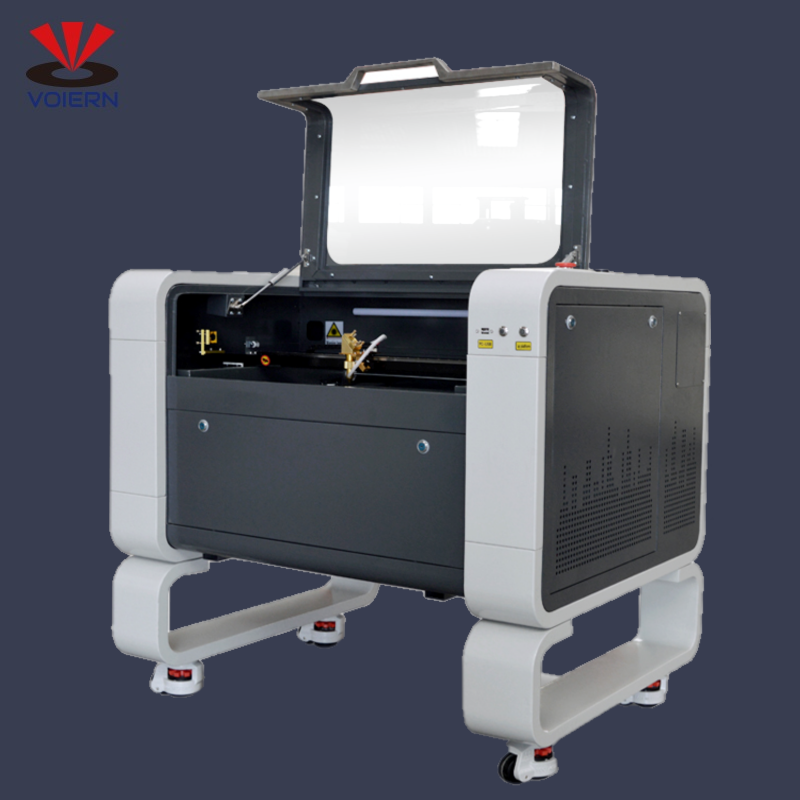

WER-6040(co2 laser engraving machine)

As a laser cutting machine manufacturer voiern CO2 laser engraving machine is the most powerful laser equipment , almost all materials can be processed perfectly.

Product Specification:- Machine size : 1400*790*980mm

- Machine color : Grey-yellow

- Working area : 600*400mm

- Engraving thickness : 2mm(depends on material)

- Cutting thickness : 2cm(depends on material)

These Machine accessories May you like

These Machine accessories May you like

-

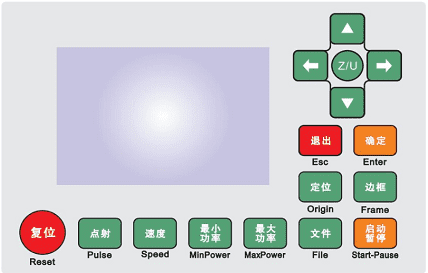

RUIDA V8 CONTROL SYSTEM

Voiern co2 laser engraving machine have powerful processing functions, visual operation and easy to learn , can meet almost all customer processing requirements.

-

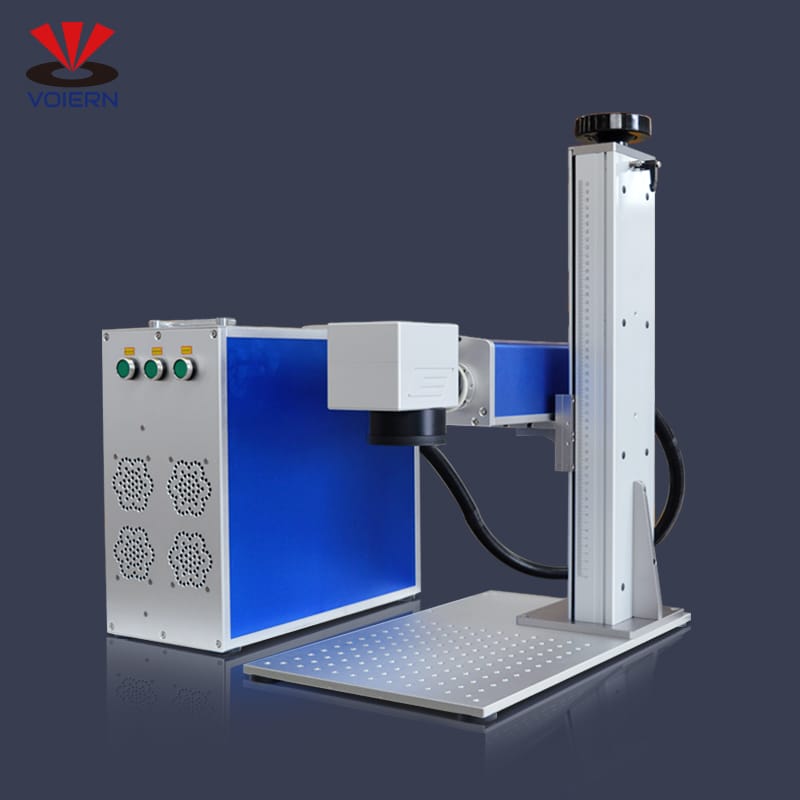

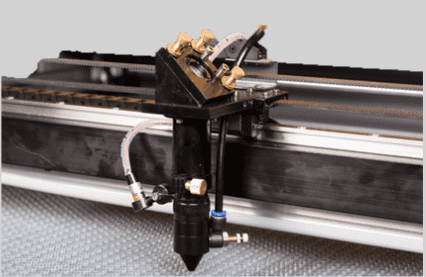

INDUSTRIAL LASER HEAD

INDUSTRIAL LASER HEADThe laser head of co2 laser engraving machine enclosed jet design protects the lens from dust and keeps the lens highly translucent.

-

HIGH-SPEED MOTORS

With 57 stepper motors, the engraving speed of co2 laser engraving machine can reach 1000mm/s and the cutting speed can reach 500mm/s.

-

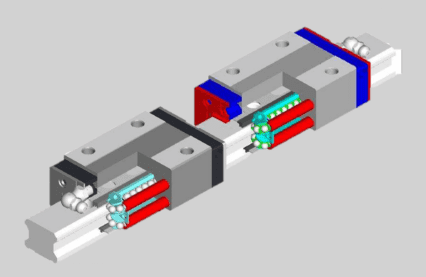

H-Q GUIDE LINEAR RAIL

CO2 laser engraving machine have stainless steel guide rail, moving slider bearing design, smaller friction coefficient, higher precision, faster operation with 57 motor.

-

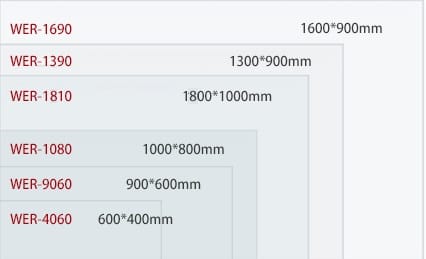

OPTIONAL WORKING AREA

From 400mm*600mm to 900*1600, co2 laser engraving machine meets the requirements of various sizes of materials for the job format.

-

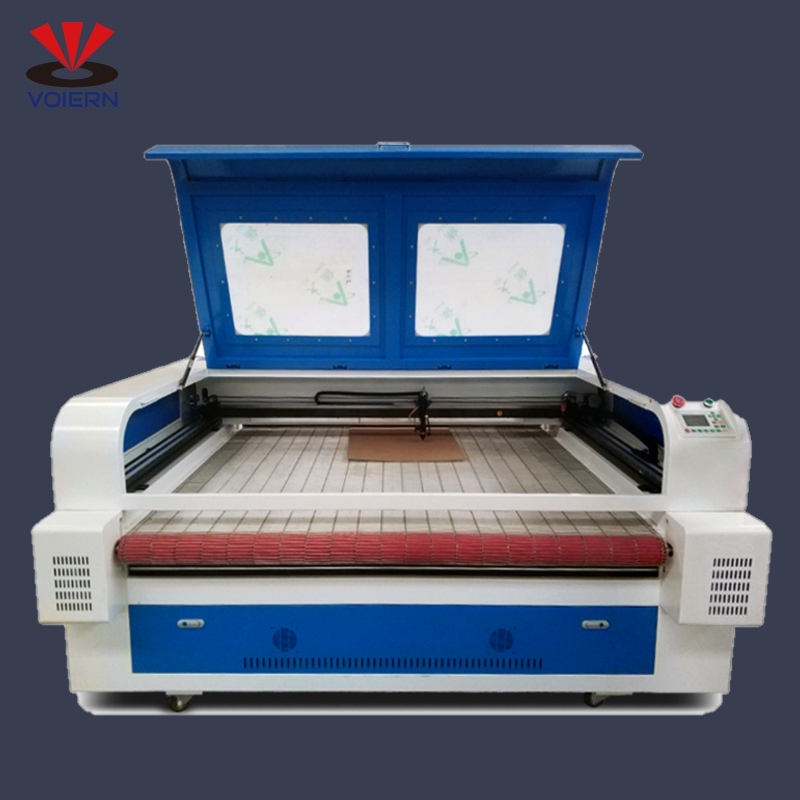

FRONT AND REAR MATERIAL DESIGN

Voiern co2 laser engraving machine remove the size limit of the processed material, so that the length of the material is increased to an infinite length.

-

HEIGHTENING MACHINE BOX

CO2 laser engraving machine increase the height of the Z axis to meet the height requirements of materials such as large volume and shape.

-

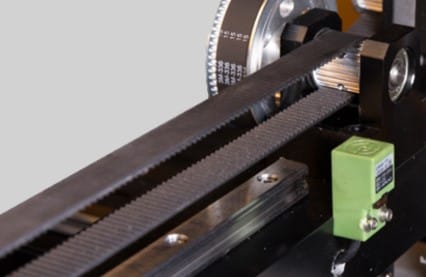

3M CONVEYOR BELT

The famous brand conveyor belt be used in co2 laser engraving machine guarantees a longer service life. the high quality belt has less stretching and deformation so that the operation accuracy is not affected.

-

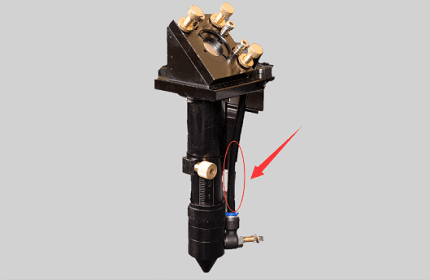

AIR BLOWING

It can protect the lens from smoke pollution, ensure light transmission, remove excess heat and impurities, and prevent or reduce the possibility of scorch.

-

IMPORTED LENSES

Voiern co2 laser engraving machine use High-Quality imported lenses ensure more precise beam focusing, finer beam and longer life.

-

LASER TUBE

CO2 laser engraving machine use laser tubes of famous brand like RECI ,WEIJU , EFR ensures the stability of the light source and service life.

-

VARIABLE STARTING

The V8 system sets a variable starting point for work, allowing you to work at any point within the working area.

| TYPE | WER-6040 | WER-9060 | WER-1080 | WER-1390/1690 |

| Machine size | 1400*790*980mm | 1400*980*980mm | 1450*1140*980mm | 1850*1310*1125mm/2150*1430*1125mm |

| Machine color | Blue-White, Gray-Yellow | |||

| Working area | 600*400mm | 900*600mm | 1000*800mm | 1300/1690*900mm |

| Engraving thickness | 2mm (depends on material) | 2mm(depends on material) | 2mm(depends on material) | 2mm(depends on material) |

| Cutting thickness | 2cm(depends on material) | 2cm(depends on material) | 2cm(depends on material) | 2cm(depends on material) |

| Engraving speed | 1-1000mm/s | 1-1000mm/s | 1-1000mm/s | 1-1000mm/s |

| Cutting speed | 1-500mm/s | 1-500mm/s | 1-500mm/s | 1-500mm/s |

| Laser power | 60w/80w/100w | 60w/80w/100w | 60w/80w/100w/1350w/150w | 60w/80w/100w/1350w/150w |

| Laser type | sealed CO2 laser tube | sealed CO2 laser tube | sealed CO2 laser tube | sealed CO2 laser tube |

| Cooling mode | water cooling protection system | water cooling protection system | water cooling protection system | water cooling protection system |

| Water protection | yes | yes | yes | yes |

| Positioning way | red light positioning | red light positioning | red light positioning | red light positioning |

| Locating precision | <=0.01mm | <=0.01mm | <=0.01mm | <=0.01mm |

| Working platform | Honeycomb/Blade platform | Honeycomb/Blade platform | Honeycomb/Blade platform | Honeycomb/Blade platform |

| Lift range | 0-250mm | 0-250mm | 0-250mm | 0-350mm |

| Power supply | AC220V/110V 50HZ | AC220V/110V 50HZ | AC220V/110V 50HZ | AC220V/110V 50HZ |

| Net weight | 120kg | 180kg | 200kg | 380kg/420kg |

| Package | Standard plywood case | Standard plywood case | Standard plywood case | Standard plywood case |

| System environment | WindowXP/win7/8/10 | WindowXP/win7/8/10 | WindowXP/win7/8/10 | WindowXP/win7/8/10 |

| Control software | Coreldraw/RUIDA V8 | Coreldraw/RUIDA V8 | Coreldraw/RUIDA V8 | Coreldraw/RUIDA V8 |

| Material | Engraving | Cutting |

| Acrylic | √ | √ |

| wood | √ | √ |

| bamboo | √ | √ |

| glass | √ | |

| leather | √ | √ |

| paper | √ | √ |

| rubber | √ | √ |

| textile | √ | √ |

| plastic | √ | √ |

| metal | ||

| stone | √ | |

| ceramic | √ |

FAQ of co2 laser engraving machine

laser cutting machine manufacturer

1. Connect computer to co2 laser engraving machine with date lines but it does not work.

A. Check the date lines, do not use long date lines.

B.Check the USB port. It works or not.

C. Check the date line and Softdog. make sure they all are plugged into computer.

2. Engraving depth of co2 laser engraving machine is not uniform.

A. Close the machine and after 1 hour start it check if there is water in water pipe.

B. Check the light path, and adjust it( refer to vedio of adjusting light ).

3. Turn on the switch of co2 laser engraving machine, but is does not work.

A.Check the power lines, it is connecting or not.

B. Check the scram button, make sure it is closed.

4. The carving depth of co2 laser engraving machine is too shallow.

A. Adjust the light path to make sure the light is at the center.

B. Check the lens, and make sure they are clean.

5.Engraving blurred image.

A:Put the focusing mirror back or wrong focusing length. You should square the lens. Adjust to the specified

focal length.

6. CO2 laser engraving machine has spark.

A:Poor electrical contact, or the air is too damp.You should connect the wire, clean the dust, keep air ventilate

and dry.

7. Engraving dislocation or stop engraving.

A:Electrostatic interference with the motherboard or signal transmission error. You should install and check the

ground wire, update the data cable or change the computer.

8.The laser head of co2 laser engraving machine not has light.

There are 4 points to be check:

(1) Check electric current. Press“TEST”button on machine screen board.If there is not electric current showed

on screen board, you should try to make sure all wires are connected well. If there is electric current showed

on screen board, maybe the lens is broken,laser tube light exit and lens are contaminated. Or the light path

offset.

(2) Check water cycle. If there is not water cycle, maybe the water pump damage. If there is water cycle, please

check whether the inlet and outlet are connected in reverse, or pipe fractures.

(3) If a dot emit light. If there is not a light,please check the wire between the engraving machine control board

and the power supply is in good contact.

(4) If above is no problem, maybe machine power damages, you should repair it.

More about co2 laser engraving machine co2 laser engraving machineplease contat to us