How to choose best laser marking machine

Voiern

Voiern  June 17,2025

June 17,2025

When choosing a laser marking machine, the best is not necessarily the most expensive, the most expensive is not necessarily the most suitable. Let Voiern laser give you some tips on choosing best laser marking machine.

1, marking machine laser source

First, confirm the material of your product. Because different materials absorb laser wavelengths differently, different laser wavelengths are named as different laser sources. Therefore, different laser sources should be used for different materials.

How to choose best laser marking machine

Fiber laser marking machine, wavelength 1064nm, the main fields of application: hardware, plastics, label paper, etc.;

Carbon dioxide laser marking machine (CO2 laser marking machine), wavelength 10.6μm, the main fields of application: bamboo, cloth, ceramics, acrylic, leather, etc.;

UV laser marking machine (UV laser marking machine), wavelength 355nm, the main application areas: silica gel, UV plastic, paper, glass and other thermal materials;

Green laser marking machine, wavelength 532nm, the main areas of application: film, fruit, eggs, cartons, tempered glass and other thermal materials.

Can a material be engraved with only one laser source? Of course not, some materials are suitable for a variety of laser sources, but the degree of laser absorption for different bands is different, the effect is good and bad, see the user's acceptance. For example: glass engraving can use three kinds of laser sources: carbon dioxide, ultraviolet and green light.

How to choose best laser marking machine

Carbon dioxide laser marking machine - rough glass, easy to produce glass slag;

Ultraviolet laser marking machine - cold light source, glass marking is very fine and uniform;

Green laser marking machine - glass engraving, internal plane engraving.

Voiern laser reminds you: to determine what laser is suitable for your product, you need specific test samples to see the final effect. The point is: proofing!

How to choose best laser marking machine

2, marking machine power

Laser power is sometimes the key to determining speed and effectiveness. Different laser sources have a most stable power range:

Fiber laser marking machine 20W/30W power is the most stable;

CO2 laser marking machine 30W power is the most stable;

UV laser marking machine 3W/5W power is the most stable;

The green laser marking machine 3W/5W power is the most stable.

How to choose best laser marking machine

Choosing the right power depends on the product material, such as UV engraving paper, film, plastic, and marking with low power 1.2W. If engraving glass, it needs UV 3W, even 5W power to be engraved.

The second look at efficiency, such as playing hardware generally with fiber optic 20W marking, if the pursuit of efficiency, speed, the use of fiber 30W high power is of course more efficient.

Of course, if you decide whether the power you are purchasing is the most suitable, it is recommended to test with specific samples, depending on the effect and marking time.

How to choose best laser marking machine

3, marking machine hardware configuration

The main hardware structure of the laser marking machine:

How to choose best laser marking machine

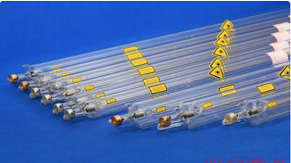

(1), laser tube

That is, the laser source, the core of the laser marking device, is installed in the equipment casing. The fiber laser imported in the past has a good output mode and long life. In recent years, the technology of the domestic laser industry is becoming more and more mature. The life and performance of the laser can be comparable to imported lasers. However, users with very high precision requirements are advised to explain and make requests to the manufacturer in advance.

Voiern laser provides domestic and imported lasers as optional; domestically selected well-known brands RAYCUS, JPT fiber lasers, imported from the US IPG.

How to choose best laser marking machine

(2), laser scanning galvanometer

The optical scanning galvanometer is also the core component of the laser marking machine. It is mainly used for the fast and precise positioning of the beam. The performance of the galvanometer determines the accuracy of the marking machine.

Voiern laser uses a high-speed scanning laser galvanometer system. The laser wavelength is different, and the laser scanning galvanometer also needs to match the four types of scanning galvanometers: fiber galvanometer, CO2 galvanometer, ultraviolet (355 galvanometer), and green light (532 galvanometer).

How to choose best laser marking machine

(3), focusing system

The focusing system focuses the parallel laser beam on one point, mainly adopting f-θ lens (also called field lens). Different field mirrors have different focal lengths, and the marking effect and range are different. The standard field lens of the fiber laser marking machine Generally: f=160mm, effective marking range Φ=110*110mm, users can choose the field mirror model according to their own products and the marking range:

f=100mm, effective marking range Φ=75*75mm

f=160mm, effective marking range Φ=110*110mm

f=210mm, effective marking range Φ=150*150mm

f=254mm, effective marking range Φ=175*175mm

f=300mm, effective marking range Φ=220*220mm

f=420mm, effective marking range Φ=300*300mm

Due to the different wavelengths of the laser source, the focusing system also needs to be divided into a fiber field mirror, a CO2 field mirror, an ultraviolet (355 field mirror), and a green light (532 field mirror).

How to choose best laser marking machine

(4), laser power supply

The input voltage of the laser power supply is AC220V AC, and the Voiern laser is a peripheral switching power supply, which is convenient for carrying and emergency stop.

How to choose best laser marking machine

(5), computer control system

The combination of laser processing system and computer numerical control technology constitutes an efficient and automatic processing equipment, which can produce various characters, patterns, symbols, one-dimensional codes, two-dimensional codes, etc. It is easy to design the marking pattern with software, change the marking content, and adapt to modern production. High efficiency, fast paced requirements.

There are many kinds of software used on laser marking machines, some of which are conventional, some are developed by themselves, or the secondary software is used for secondary development. It mainly depends on what control card the equipment manufacturer uses and decides which software to use.

The first one: Beijing Golden Orange, marking software for EZCAD, this software is the most used, currently the laser equipment manufacturers of small machines generally use this software, the design of this software is also more, the main problem is two The development is difficult.

How to choose best laser marking machine

The second type: Taiwan Qingyi software, this paragraph is quite satisfactory, can meet the general needs, the secondary development is more difficult, domestic users are relatively less than golden oranges, but foreign countries such as Thailand, India and other places generally use this software. More.

The third type: LS8001 software and marking machine, this model is not many users, but its advantage is that the secondary development is not difficult, can easily complete and add unused functions, but the software maintenance cost is high after the sale. .

At present, the models used in the Voirn laser are basically equipped with software for Golden Orange.

How to choose best laser marking machine

Support: Freely designed graphic patterns, support for TrueType fonts, single line font (JSF), dot matrix font (DMF), 1D barcode and DataMatrixdeng.

The marking software is simple and powerful, and is compatible with the output files of software such as CoreIDRAW, AutoCAD, Photoshop, etc. It also supports PLT, DXF, JPG, BMP and other files.

How to choose best laser marking machine

4, the life and stability of the marking machine

Lasers are gradually lost during long-term use. Many people mistakenly believe that the larger the laser power, the longer it consumes, and the longer the laser life. In fact, the greater the laser power, the more heat is generated during operation. If the heat is not dissipated in time, the long-term high temperature of the equipment will shorten the life and burn out easily.

Therefore, equipment with 50W fiber and 3W UV or more needs to be equipped with a large cooling system for water cooling. Therefore, the higher the wattage, the longer the life cannot be guaranteed. If the cooling system is not well done, it is more likely to burn out and increase the cost of heat dissipation.

How to choose best laser marking machine

Voiern laser specializes in providing laser equipment with a life expectancy of 60,000 to 100,000 hours in a working environment with good temperature and humidity.

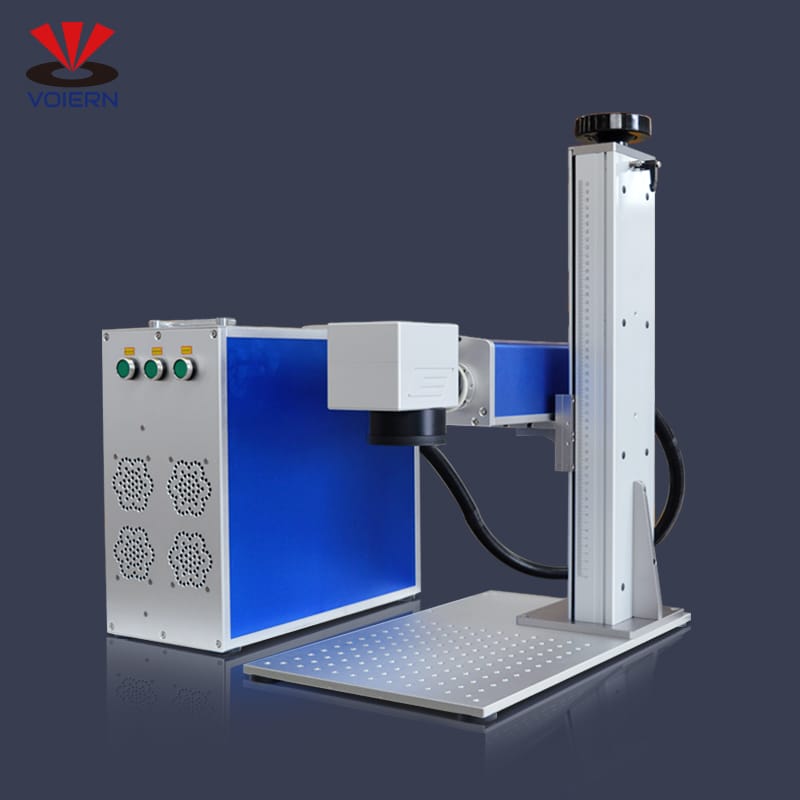

At present, the appearance of the laser marking machine includes a small portable laser marking machine, a desktop laser marking machine with a cabinet operating table, a computer, and a flying laser marking machine for the automatic assembly line.

How to choose best laser marking machine

5, marking machine after-sales service

The operation of the laser marking machine requires engineer guidance and training. In particular, the application skills, parameters and routine maintenance of the equipment marking software.

The warranty period for electronic products is one year, and some manufacturers will promote the warranty period of three years and five years to attract customers. In fact, the accessories of the laser marking machine are selected well, because the equipment has no consumables, no consumable parts, and the equipment has high maintenance-free rate. Today's laser equipment has a lifespan of 60,000 to 100,000 hours, and there is no problem in three to five years.

When the working environment temperature and humidity are good, there are after-sales engineers responsible for docking customers, so that you can worry about after-sales.

When the working environment temperature and humidity are good, as a manufacturer specializing in the production of laser marking machines - quality, integrity, service - is our commitment.

How to choose best laser marking machine

6, about customization and other

When the laser equipment is used, the requirements for precision, engraving effect, speed, and automation, customization, etc. must be submitted to the manufacturer in advance, and confirmed during the sample measurement and the program, so as to avoid the purchase of a marking machine that does not meet the user's requirements. Affect the user experience.

Voiern laser's fiber laser marking machine: integrated design, small size, low power consumption, long life, high efficiency, maintenance-free, high-quality laser beam, fine spot, no consumables.

The UV laser marking machine has small focusing spot, low thermal impact and fast speed. It is mainly used for ultra-fine marking and is widely welcomed by food and pharmaceutical packaging manufacturing.