Flexible Application of Laser Marking Technology in Electronic Industry

Voiern

Voiern  June 17,2025

June 17,2025

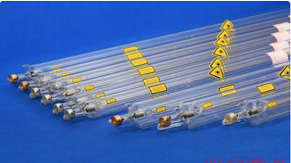

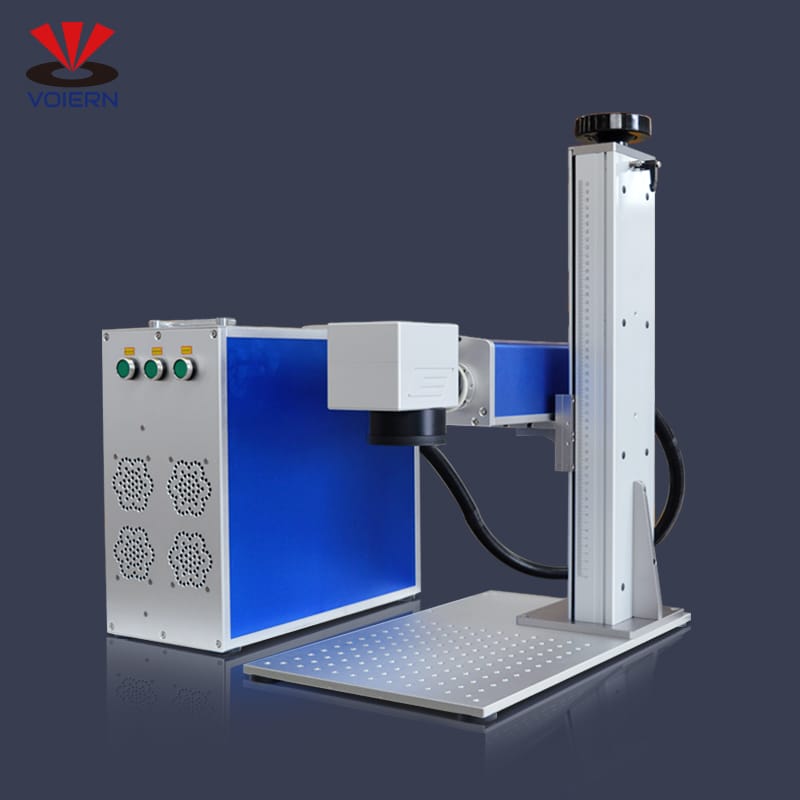

Laser marking machine market is the fastest growing application technology in recent years. Laser marking is a technology that uses high energy density laser to irradiate the workpiece locally, to vaporize or change the color of the surface material, thus leaving a permanent marking.

Laser marking has many unique advantages. It can mark all kinds of cosmic lines, patterns, numbers and barcodes, and its linewidth can be less than 0.0lmm. Laser marking is permanent, unlike ink-jet printing, which can be erased; it can be used as anti-counterfeiting marking. It is not easy to be counterfeited; it belongs to non-contact processing, so there is no damage to the surface of parts; the parity of marking is clear and the graphics quality is good; the efficiency is high and the cost is low, so it can mark many kinds of materials; the marking content can be easily replaced by a juice computer operation, and a part can be marked one by one; because of the above characteristics, it is more and more widely used, especially a variety of electronic devices and integration. Circuit modules, automotive parts and even automotive windows, wires, connectors, tools, medical devices, precision instruments, circuit boards, rubber products, computer keyboards, mobile phone panels, exquisite gifts, glass products and so on.