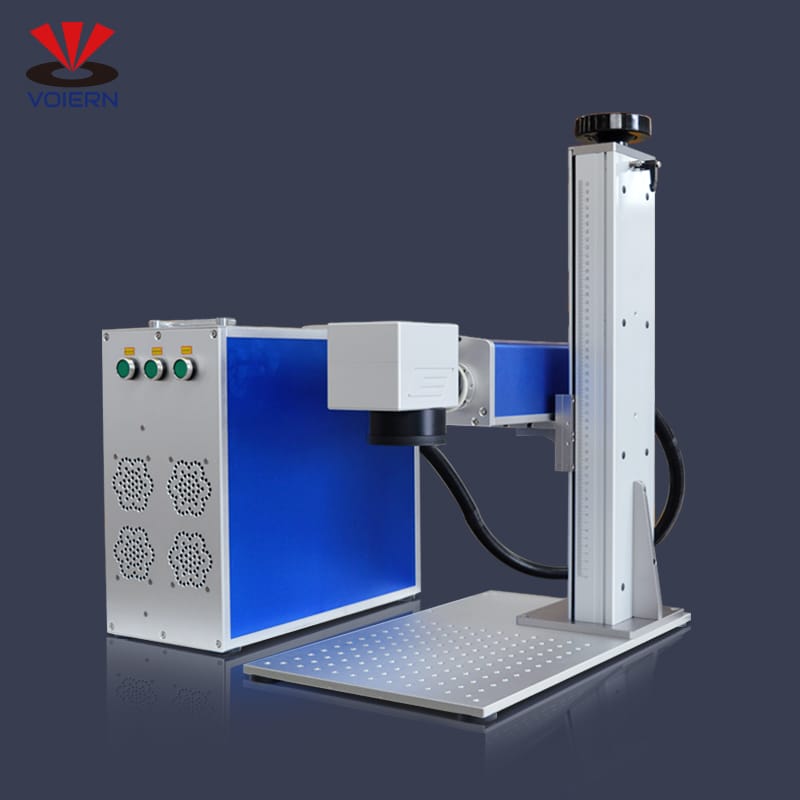

Stamp laser engraving machine

Voiern

Voiern  June 17,2025

June 17,2025

Stamp laser engraving machine is a high-tech product that integrates the latest optical, machine and electric integration technologies and design solutions. The main working principle is to rely on the laser tube to generate laser light. The laser carries high temperature on the chapter material for progressive scanning engraving. The laser engraving machine can engrave on hard materials such as plastic, horn, organic, etc., and can only be processed on non-metal materials.

Machine introduction

The new generation Voiern stamp laser engraving machine has the best combination of appearance, performance and precision. Its WINDOWS (recommended to use win98/me/xp/2000) full Chinese interface display, support printer, scanner, compatible with TIF international standard font and BMP, The JPG file, at the same time, its engraved seal effect can fully meet the "China People's Republic of China and the Public Safety Industry Standards" (GA241.-2000). Simple operation, font specification, easy to learn and use, positive words, anti-words, yin and yang words can be converted at will.

working principle

The Stamp laser engraving machine is powered by a power supply to the laser, which emits laser light to the reflective lens and then focuses the engraving on the material through the lens.

Advantage characteristics

Stamp laser engraving machine is the most advanced processing tool. It mainly uses high-efficiency laser to engrave and cut materials. The main equipment includes computer and laser engraving machine (cutting machine). The process of laser engraving and cutting is very simple, just like using Computers and printers print on paper. After using a variety of graphics processing software (CorelDraw, Photoshop, CAD) for graphic design, the graphics are transferred to the laser engraving machine. The stamp laser engraving machine can easily engrave the graphics to any material. Surface and edge cutting as required by the design.

Advantages of stamp laser engraving machine:

1: Wide range: the stamp laser engraving machine can engrave and cut almost any non-metallic material. And the price is low.

2: Safe and reliable: the stamp laser engraving machine uses non-contact machining without mechanical compression or mechanical stress on the material. No knife marks, no damage to the surface of the workpiece; no deformation of the material.

3: Accurate and meticulous: the processing accuracy of the stamp laser engraving machine can reach 0.02mm.

4: Environmental protection: the beam and spot diameter of the stamp laser engraving machine is small, generally less than 0.5mm; the cutting process saves materials, safety and hygiene.

5: The effect is consistent: the stamp laser engraving machine ensures that the processing results of the same batch are exactly the same.

6: High speed and quick: the stamp laser engraving machine can immediately engrave and cut at high speed according to the pattern output from the computer.

7: Low cost: the stamp laser engraving machine is not limited by the number of processing, laser processing is cheaper for small batch processing services.

Carved material

1.stamp laser engraving machine is suitable for non-metallic materials such as: horn print, wood print, red plastic print, plexiglass print, atomic print, crystal print, soft jade print.

2.stamp laser engraving machine is suitable for small-area handicraft processing, carving all kinds of graphics and text on two-color board, wood board, bamboo piece, plexiglass board, acrylic, cloth.

3.stamp laser engraving machine can engrave names, models, logos, patterns, etc. on electronic components, which is extremely permanent.

Stamp laser engraving machine system

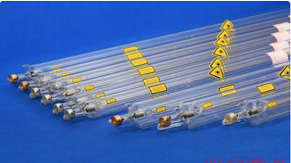

1. Carbon dioxide laser (co2 laser tube).

2. Laser power supply (both high voltage package power supply and high voltage box power supply).

3. Control panel (including power switch, laser switch test switch, lighting switch, current adjustment, current display and other function keys).

4. Plane workbench (for fixtures and clips).

5. Optical path system (consisting of lens holder and plane mirror).

6. Cooling system.

7. Smoke exhaust system.

8. Motherboard (the main control part).

9. Computer engraving machine software (encryption lock software and registration code software).

10.USB cable (connecting important links between computers and machines).

installation