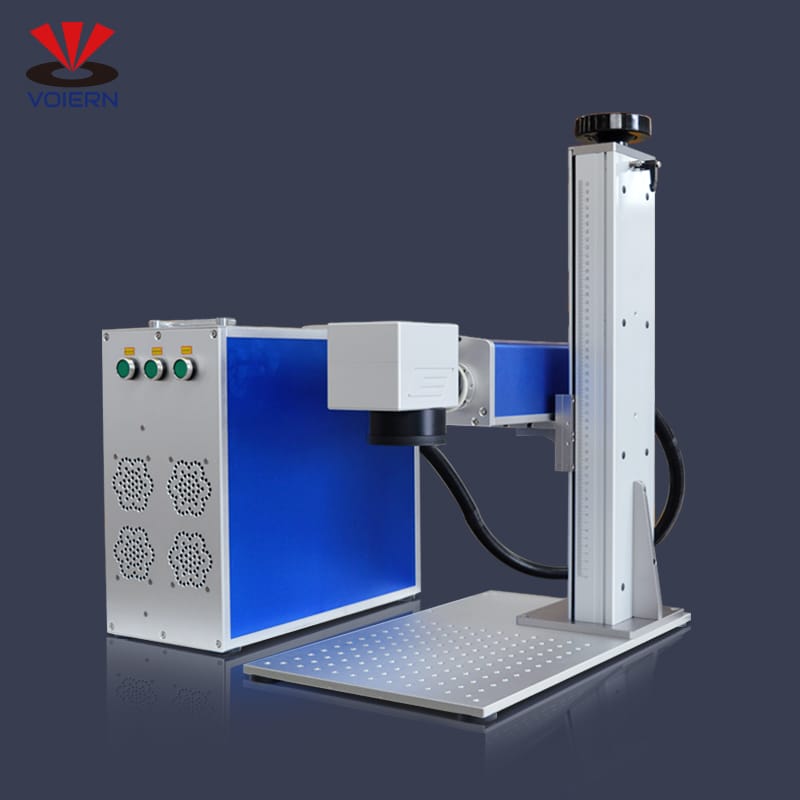

MOPA color laser engraving machine

Voiern

Voiern  June 17,2025

June 17,2025

Let's take a look at the color laser engraving machine for color marking on stainless steel. Use the MOPA laser color laser engraving machine. The advantage of the MOPA laser is that its pulse width and frequency are independently adjustable, and adjusting one of them does not affect other laser parameters, which is not available in other structural lasers. The MOPA structure has an infinite variety of possibilities for stainless steel color marking. In the actual marking operation, the pulse width, frequency, power, speed, filling mode, filling pitch, delay parameters and other factors will affect the color effect. The influence of these parameters will make the characteristics of color change not unique, but they are related to each other.

The principle of the color laser engraving machine is to use an advanced MOPA laser to generate high temperature by laser focusing to expose the surface material of the material to reveal deep substances, or to display the mark information by the chemical and physical changes of the surface substances caused by light energy.

The principle of color development of stainless steel: There are three ways of color development: one is to produce colored oxides; the other is to produce a very thin colorless transparent oxide film on the stainless steel surface by chemical, electrochemical or laser action, and the oxide film interferes. The effect, which can be displayed on the surface, is a mixed state of colored oxide and oxide film.

color laser engraving machine

Stainless steel laser color marking principle: stainless steel material under the action of laser heat surge, the surface generates colored oxide, or a layer of colorless transparent oxide film, which is rendered by various modes of light interference. It is the basic principle of stainless steel color marking. The oxidized product of the metal element in the stainless steel itself also exhibits a color.

color laser engraving machine

Under the action of laser, the surface of the stainless steel produces a laser thermal effect. Through the laser thermal effect, the laser energy density is proportional to the film thickness. As the laser energy increases, the color of the stainless steel surface exhibits regular variations: yellow, red, blue, green, and green until the green becomes darker and deeper. By controlling the laser energy density, you can create the desired color on stainless steel products.