Glass cup laser engraving machine

Voiern

Voiern  June 17,2025

June 17,2025

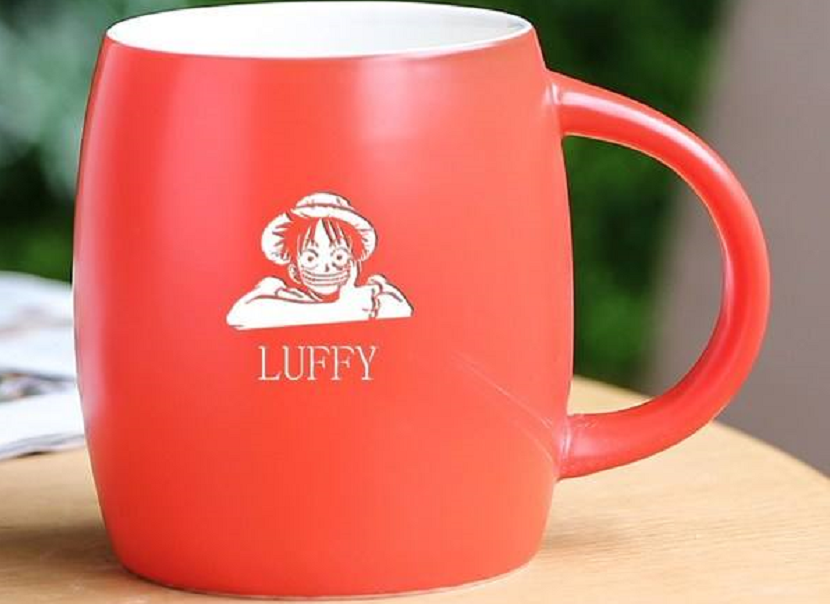

It is common in some life to have some beautiful carving techniques on the cups. These techniques are basically all laser-engraved, mainly because laser engraving can maintain the consistency of the product pattern more than manual engraving, and then a laser engraving. The speed is more refined than manual engraving, the efficiency is higher, and the damage in production is also small. Let's take a look at the related content of laser engraving.

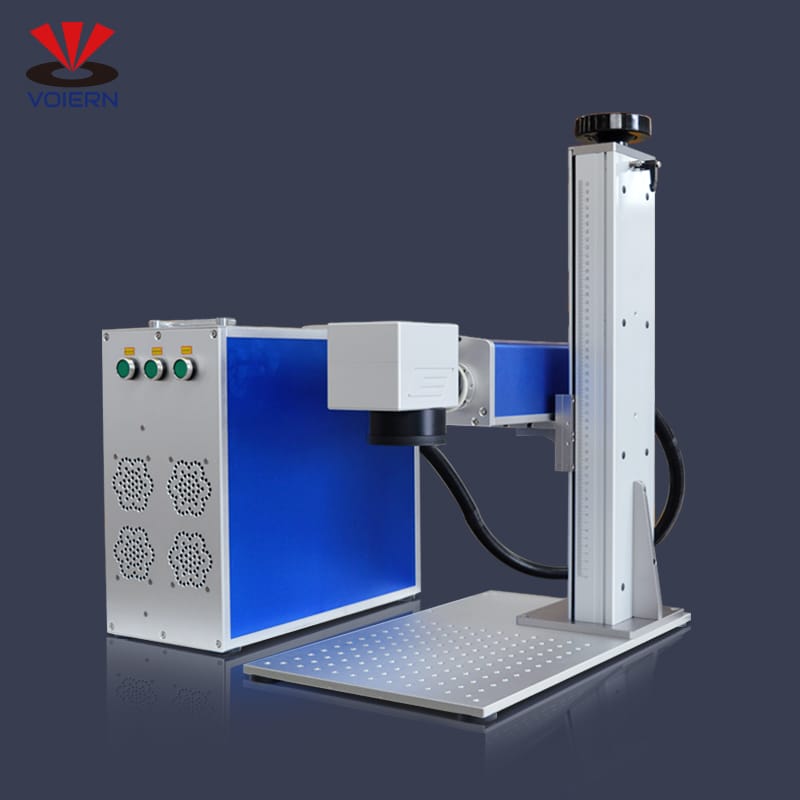

Glass cup laser engraving machine

Definition

Laser engraving glass products refer to the physical deformation of the glass by micro-machining medium based on computer control technology to melt and vaporize the glass under laser irradiation to achieve the purpose of engraving patterns.

Glass cup laser engraving machine

Characteristics

1. Laser engraving efficiency is high, engraving time is very short, more than 100 times higher than mechanical engraving efficiency;

2. Due to the directionality and monochromaticity of the laser, it can be concentrated to the order of a certain wavelength, and accurate micro-area processing is difficult to achieve by other methods;

3. Laser engraving without mechanical contact, no tool wear and tear, and will not affect the properties of the glass;

4. The laser processing speed is very fast, and the heat cannot be spread to the adjacent area within one thousandth of a second, and the glass product is not deformed;

5. Laser engraving does not cause a lot of pollution, which is conducive to environmental protection;

6. Laser engraving is easy to automate and flow.

Glass cup laser engraving machine

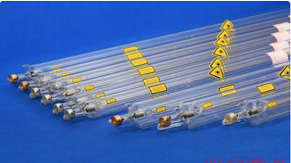

Laser type

There are basically two kinds of laser light sources for glass engraving patterns. One is a CO2 laser tube, which is relatively inexpensive and has a service life of several thousand to ten thousand hours. The machine using this laser tube is generally laser engraved. Machine, engraving speed is less than 1000mm / s, the format is basically no limit, the other is UV UV laser tube, the machine using this laser tube is called uv laser marking machine, the price of this machine is generally 5-10 Ten thousand yuan, but the service life is tens of thousands of hours, the working format is limited, generally within 300 * 300mm, this laser source is cold light, does not burn processed materials, has more advantages than other types of laser.

Glass cup laser engraving machine

Laser engraving cup maintenance

Since the laser-engraved cup has a groove on the surface of the glassware, when cleaning and cleaning, the first thing to pay attention to is timeliness. When it is used, it should be cleaned in time. In a cleaning, it is necessary to clean the engraving pattern with a soft cloth or simply Brush with a soft brush and dry it with a cloth in time to avoid water stains on the surface of the cup.

Glass cup laser engraving machine