Woodcut printmaking

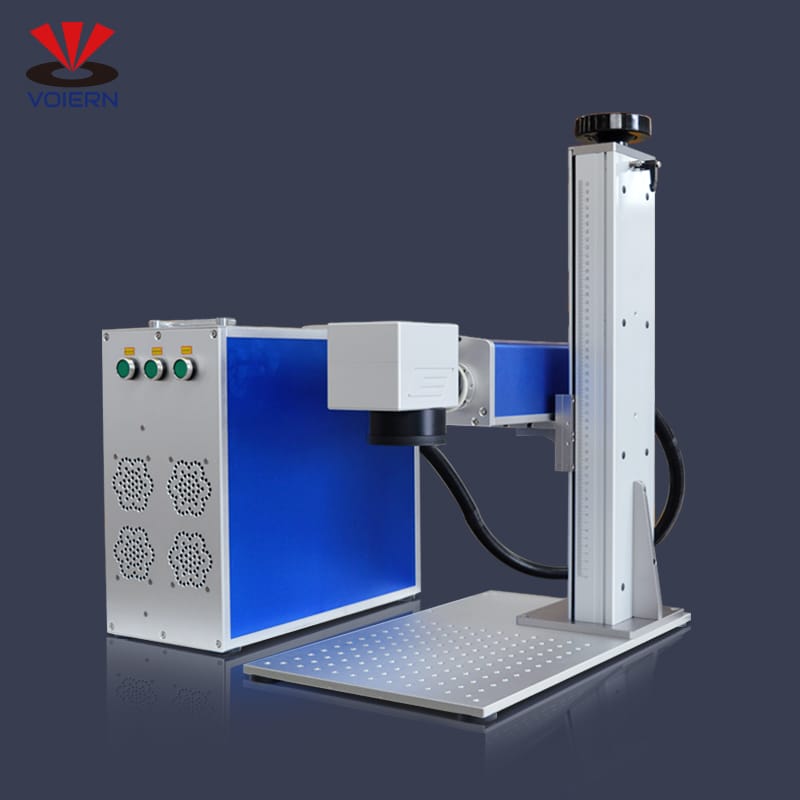

Voiern

Voiern  June 17,2025

June 17,2025

Light-colored wood such as birch, cherry or maple is easily vaporized by lasers and is therefore more suitable for engraving. Each type of wood signage has its own characteristics, some of which are dense, such as hardwood, which requires greater laser power for engraving or cutting. We recommend studying the engraving properties first before carving less familiar wood.

Plywood:

Carving on plywood is not much different from carving on wood, but one thing to note is that the depth of engraving should not be too deep. The edge of the cut plywood will also be black like wood. The key is to see if the plywood is made of that kind of wood.

Woodcut printmaking

Wood Carving: Wood Carving In general, carving on wood is usually a vulture, and the depth of engraving is generally required to be deep. This power is generally set higher, such as encountering harder wood may make the engraved graphics color darker. If you want to make the color lighter, you can increase the speed of engraving and try to sculpt several times. Woodcut printmaking

Some woods will produce some fumes attached to the surface of the wood. If the wood has been painted with a damp cloth, it can be carefully wiped off. If it is not painted, it may not be cleaned, causing the surface of the finished product to be stained.

Woodcut printmaking

Wood cutting:

The depth of cutting wood by laser engraving machine is generally not deep. The maximum cutting depth depends on the material of the wood and the power of the laser. If you want to cut thick wood, it can slow down the cutting speed, but it may cause the wood to burn. For specific operations, try using large-size lenses and repeating them.