laser etching metal

Wide range of metal marking

Laser marking is the use of a laser beam to mark permanent surfaces on a variety of different materials. The effect of marking is to expose deep substances by evaporation of surface substances, or to "engraving" traces by chemical or physical changes of surface materials by light energy, or to burn off some substances by light energy to show the desired etching. Graphics, text.

Metal is an important product material, and the use of metal is everywhere in our lives. Large to space shuttles, space stations; small to now widely used Apple phones, metal earrings on girls' ears, boys' metal belt signs. Metal has penetrated into our clothing, food and shelter, and metal products can be said to occupy a very important position. Marks used for identification, such as trademarks, bar codes, and serial numbers on metal products, are usually formed by directly machining the surface, such as stamping, engraving, punching, etc., or by external processing such as printing or labeling.

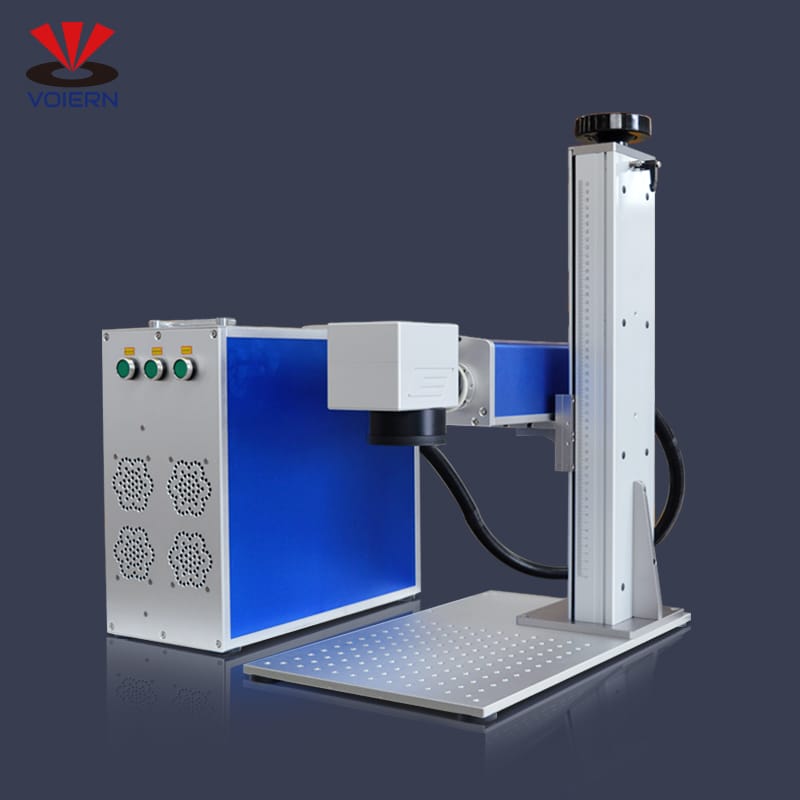

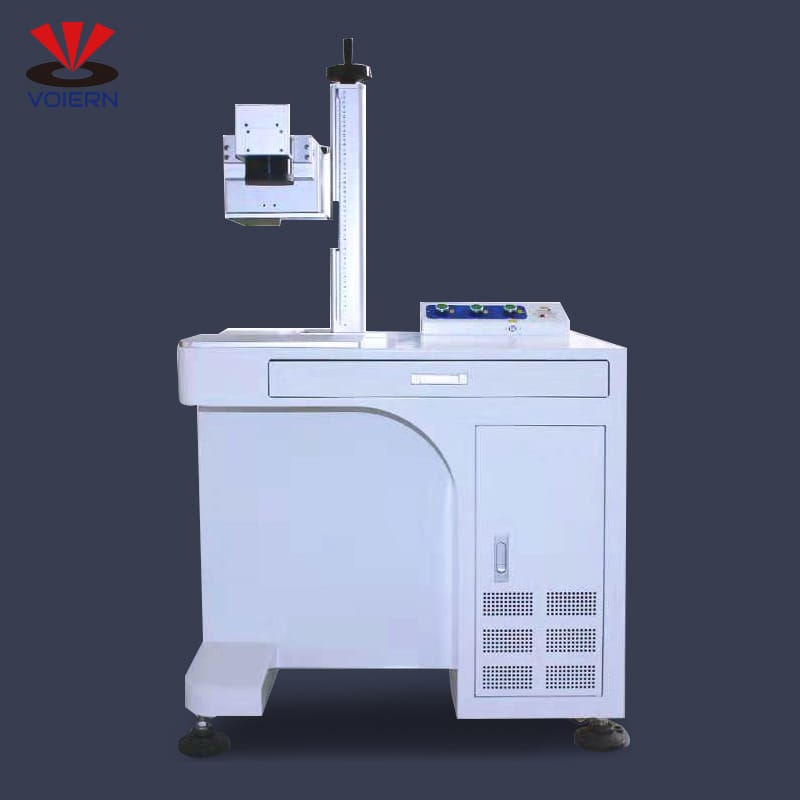

The use of laser marking machines to print marks on the surface of metal products is a new high-tech processing method. The laser processing on the metal surface not only has a very fast processing speed, but also maintains the inherent surface characteristics of the metal products, and the printed mark has Durable, anti-counterfeiting and high quality, no other processing steps are required.

Some metals are difficult to process and mark because of the material, and the traditional mechanical processing method is not efficient and slow. However, the use of laser processing is different. The speed of laser processing is very fast, and it does not destroy any substance on the metal surface. The absorption rate of laser energy is a function of wavelength. Under the same laser intensity, different metals will get different masses. The marking can be adjusted according to actual needs. One of the characteristics of the laser marking machine is that it is easy to operate.

Laser marking is of great significance for metalworking markings. Today, metal products are widely used in various industries, such as: home appliances, aerospace, automobiles, mobile phones, medical devices, lighting appliances, which are indispensable parts. . It is precisely because metal products are so indispensable in our lives that it is so important to see laser marking. For now, laser marking machines are definitely one of the most suitable processing equipment for metal marking!

Characteristics

1. Can process most metal or non-metal materials.

2. The laser is processed by non-mechanical "tool". It does not produce mechanical extrusion or mechanical stress on the material, no "tool" wear, no toxicity, and rarely causes environmental pollution.

3. The laser beam is very thin, so that the consumption of the material to be processed is small.

4. When processing, X-rays are not generated as in the processing methods such as electron beam bombardment, and are not interfered by electric fields and magnetic fields.

5. Simple operation, automatic machining can be realized by using microcomputer numerical control technology, which can be used for high-speed and high-efficiency processing of parts on the production line, and can be used as a part of flexible processing system.

6. Fine precision machining can be performed using a precision table.

7. Use the microscope or camera system to observe or monitor the condition of the surface being machined.

8. It can be processed through its light-transmissive materials (such as quartz and glass).

9. It is possible to use a prismatic, mirror system (for Nd:YAG lasers, it is also possible to use a fiber optic light guiding system) to concentrate the beam onto the inner or inclined surface of the workpiece for processing.

10. Can mark barcodes, numbers, characters, patterns and other signs.

11. These markers have a line width as small as 12Mm and a line depth of up to 10Mm, so they can mark zero-surfaces of "millimeter" size.