Working Principle of Home Laser Engraving Machine

Voiern

Voiern  September 06,2019

September 06,2019

Working Principle of Home Laser Engraving Machine

Laser is a kind of light, which is produced by atom (molecule or ion kite) transition and spontaneous radiation, just like its electroluminescence in nature. Laser is light, but it is different from ordinary bright display. Laser only depends on spontaneous emission in the initial very short time. The process after that is completely determined by the excitation. Therefore, laser has very pure color and almost no divergence direction.

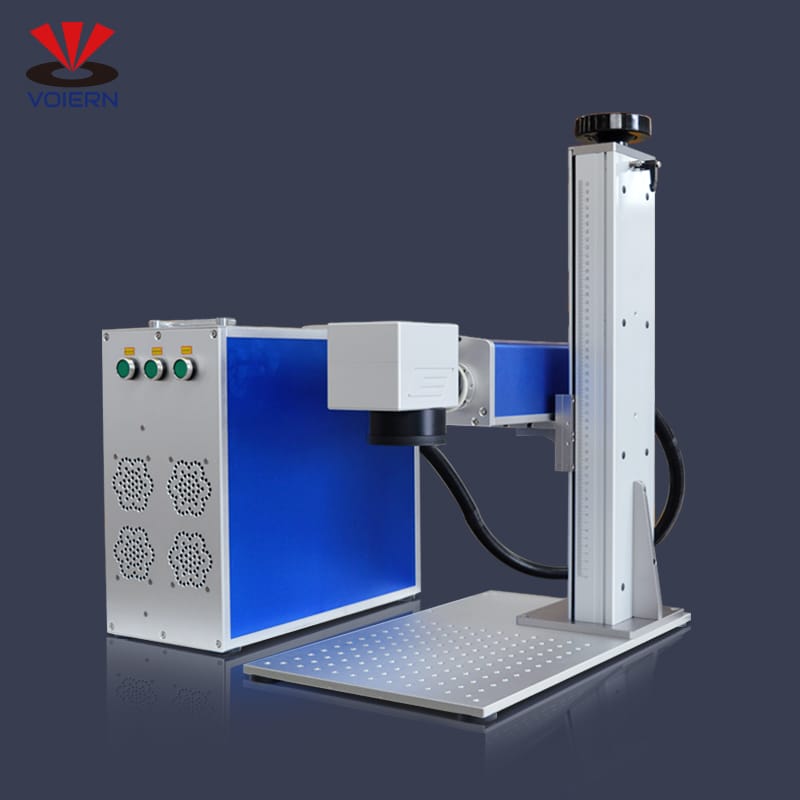

The engraving machine has very high luminous intensity, and the laser has high coherence, high intensity and high directivity. Laser is transmitted by mirror and irradiated on the processed object through the aggregating mirror after laser is produced. The temperature of the processed object (surface) increases sharply because of the strong heat energy. The point melts or vaporizes rapidly because of the high temperature, and cooperates with the trajectory of the laser head to achieve the purpose of processing.

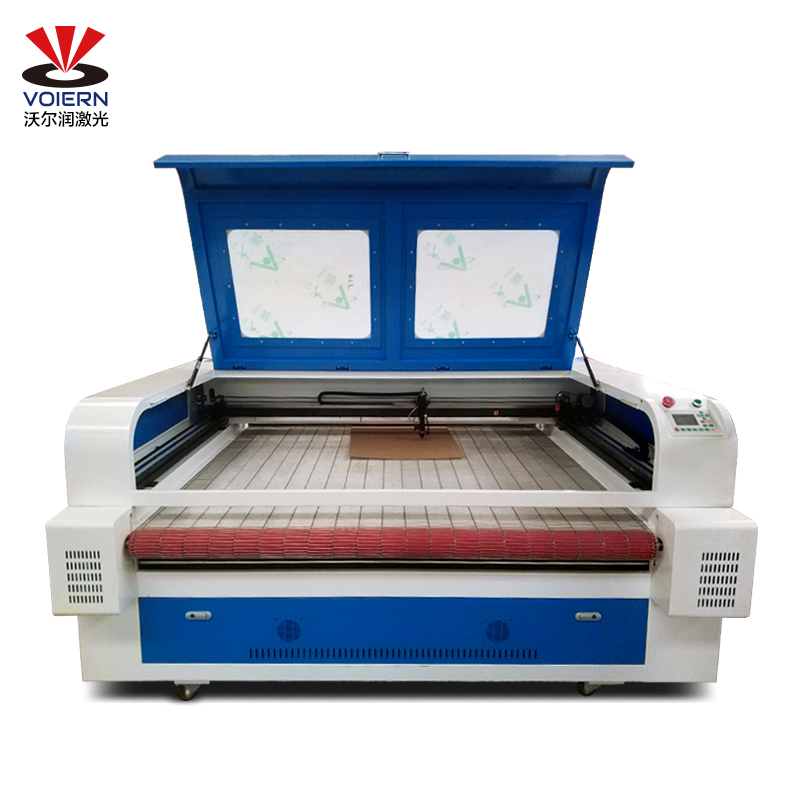

The speed of laser head movement is usually expressed in IPS (inches/seconds). High speed brings high productivity. Speed is also used to control the depth of cutting. For a specific laser intensity, the slower the speed, the greater the depth of cutting or carving. The speed can be adjusted by the engraving machine panel or by the printing driver of the computer.

In the range of 1% to 100%, the adjustment range is 1%. For a particular speed of engraving, the greater the strength, the greater the depth of cutting or engraving. The intensity can be adjusted by the panel of the engraving machine or by the print driver of the computer.