Laser engraving machine selection tips and guide

Voiern

Voiern  June 17,2025

June 17,2025

The laser engraving machine can improve the engraving efficiency, make the surface of the engraved surface smooth and round, quickly reduce the temperature of the engraved non-metallic material, reduce the deformation and internal stress of the engraved object; can be widely used for various non-metal The field of fine engraving of materials. Laser engraving machines can be roughly divided into: non-metal laser engraving machines and metal laser engraving machines. Laser cutting machine company.

In the domestic market, engraving machines can be roughly divided into: handicraft engraving machine, knife die cutting machine, floor parquet machine, acrylic cutting machine, garment cloth cutting machine. Laser cutting machine company.

With the rapid development of industrial technology, the development and promotion of laser engraving equipment in application technology and technology, the production and sales of laser plane marking and engraving equipment have also shown a good upward trend. There are many kinds of laser equipment on the market, which are summarized as follows: laser welding, laser marking, laser engraving, laser cutting, laser demonstration, laser drilling, laser platesetter, laser medical, laser cosmetic, laser heat treatment, laser Spray code and so on. They are the crystallization products of laser technology and software control technology, bringing vitality to modern industrial civilization. Therefore, in recent years, companies engaged in the development, manufacture, and sales of laser equipment in China, as well as companies that represent foreign laser equipment, have increased rapidly. Competition is also becoming increasingly fierce. How to choose your own laser engraving machine products is especially important. Laser cutting machine company.

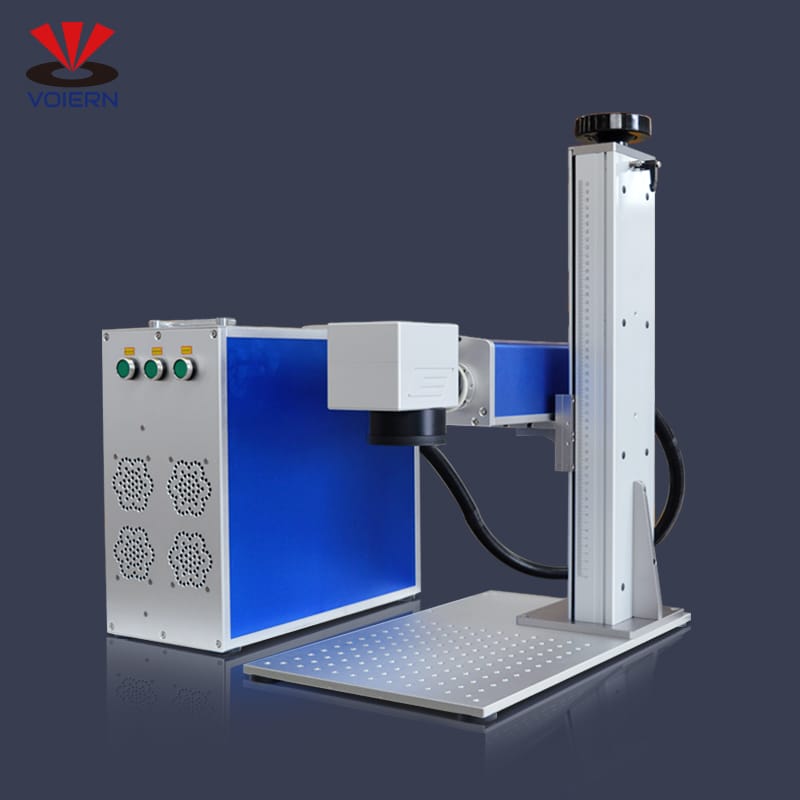

1.Know which industry you are doing. The classification of engraving machines on the market today is mainly divided into two categories: one is engraving non-metal, and the other is engraving metal. The main purpose of engraving non-metal is carbon dioxide laser tube, and the main metal engraving is fiber laser engraving machine. In addition, in addition to these two categories, there are many different types of engraving machines, such as laser welding machines, laser marking machines, laser engraving machines, laser demonstration machines, laser drilling machines, etc. Therefore, we must choose the laser engraving machine correctly according to the industry we have done and the specific content carved in our own industry. Laser cutting machine company.

2. Know the size of the product you want to process. Choose the right laser engraving machine according to the actual size of the product you want to engrave, which is the choice of the size of the laser engraving machine. For example, if the size of the product you want to engrave is: 130cm*90cm, then you can choose the model with the engraving format: 130cm*250cm, but pay attention to the large size of the machine, it is not necessarily good, because the large format equipment is not only expensive, Moreover, some machines with poor quality have unstable laser output averages at various points on the large-format processing table, resulting in different depths of engraving products on the same table. Therefore, it is also necessary to select the appropriate processing machine. Laser cutting machine company.

3. the engraving precision of the laser machine. The laser machine with high precision of engraving can naturally be favored by people. Therefore, the difference between laser engraving and traditional engraving equipment and hand engraving is high precision. Therefore, we must pay attention to the engraving precision of the laser engraving machine when selecting. The higher the engraving precision, the better the effect, and the more the products can be satisfied by consumers and customers. Laser cutting machine company.

4. laser tube power. The laser engraving machine has a lot to do with the laser tube as its name suggests, so the power of the laser tube largely determines the finished product of the engraving. This is not the case that the power of the laser tube is as high as possible. On the contrary, some materials may cause a bad effect if a laser tube with a relatively large power is used. Therefore, it is necessary to select a suitable laser tube according to the material. For example, the engraving of acrylic and two-color plates does not require a laser tube of too much power, but the engraving of wood and stone and the cutting of any material may require a laser tube of a larger power. Only then can you get twice the result with half the effort. Laser cutting machine company.

5.credibility and good after-sales. This depends on the customer's own understanding of the market and the industry is not enough. The quality of after-sales directly affects the production efficiency. If the machine that has been bought has a problem that cannot be solved, it directly causes the production to stop and can not work, so after-sales service maintenance is very important. Therefore, when customers choose laser engraving machine products, they should actively understand the market, analyze the market, and analyze which manufacturers produce machines that are better, the reputation is guaranteed, and the quality of the machines of those manufacturers is relatively good, and the engraving effect is better. The information must be mastered in the first place. Only by mastering this, you can be more comfortable when you choose to buy. Laser cutting machine company.

In summary, when choosing to purchase laser engraving machine products, we must understand the contents of these aspects. Only by understanding and mastering, when choosing a laser engraving machine, we can make correct according to our actual situation. select. Laser cutting machine company.