How to choose the best laser engraving machine?

Voiern

Voiern  June 17,2025

June 17,2025

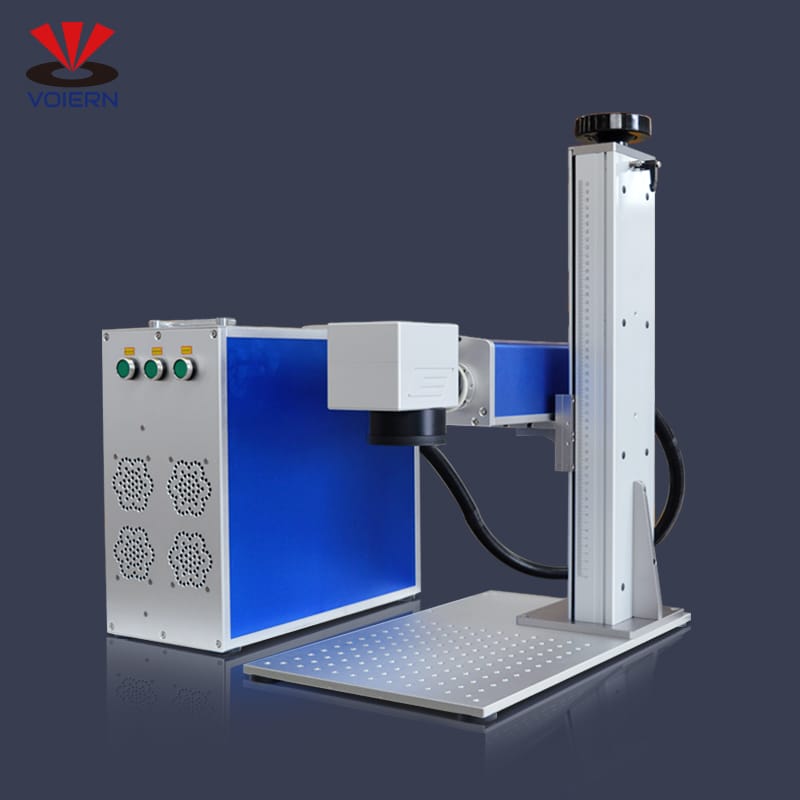

Laser engraving machines are used more and more widely in the processing of non-metallic materials, and the laser engraving machine on the market can be described as a wide variety of brands, and various so-called technological upgrades are also emerging. Domestic market laser engraving machine, the production of laser engraving machine entity manufacturers are few, a lot of is OEM, which requires everyone to polish their eyes, then when we choose the best laser engraving machine, what should we do to find the best laser Engraving machine?

Let's take a look at some of the techniques for purchasing the best laser engraving machine.

First of all, be sure to determine your own needs, select the appropriate laser engraving machine for the application industry, so that there will be a rough price range first.

1. To determine the engraving material to choose the best laser engraving machine

For example, the non-metallic laser engraving machine is selected for engraving and cutting non-metal, and the metal laser engraving machine is selected for processing metal. Because the price difference between the two is very large, the non-metal laser engraving machine is only about a few hundred dollars, and the metal laser is the cheapest. The most expensive engraving machine also got more than 10 US dollars to start.

2. To determine the processing width, that is the table size to choose he best laser engraving machine

Depending on the application industry, the laser engraving machine has a different processing format. The general laser engraving machine models are 6040, 9060, 1080, 1390, 1690, 1310, 1810, 1325. For example, the 6040 model is 600*400mm, and the processing range of the laser engraving machine is different. When other configurations are consistent, the larger the format, the higher the price.

3. Choose a professional, high-quality machine to choose he best laser engraving machine

Although most laser engraving machines can cut more than one material, we still recommend that it be professional in the field, because in the processing applications of different industries, the laser engraving machine corresponding to the professional customized model is generally aimed at the laser. The engraving or cutting has been optimized to achieve far greater results than general-purpose equipment. For example, if you are engaged in advertising, you should purchase a professional laser engraving machine for the advertising industry. If you still insist on buying a normal laser engraving machine, you must choose a laser engraving machine with a “knife bed” device. Remember: Don't believe that some manufacturers say 60w, 80w machine can cut 20mm thick acrylic, this is impossible, even if it can barely cut through, the cutting effect is very bad. The normal value is: 60w laser engraving machine can cut 8-10mm acrylic, 80w laser engraving machine can cut 8-15mm acrylic. Choose a more professional laser engraving machine. Select "one fine multi-energy" from the optimized configuration item of the model

4. Select the laser power that matches the processing requirements, not over-allocation to choose he best laser engraving machine

According to the different materials and process flow of the engraving, the appropriate number of laser tube watts should be selected to achieve the expected working effect, and it is not over-matched. After all, the equipment with high power is also expensive.

After determining the requirements, you must choose the most cost-effective equipment according to your psychological price. Here are some tips for you to choose:

1. Optimize laser engraving speed. In a short period of time, more products can be produced at a faster speed to create higher profits. The engraving speed is preferred.

2. Optimization of laser engraving precision The biggest difference between laser engraving and traditional engraving equipment and hand engraving is high precision. If it is a finely engraved pattern, of course, the precision of the engraving machine will be higher. Select which one is higher in the same price machine.

3. Start with the parts and understand the quality of the product to choose he best laser engraving machine

A laser engraving machine, the parts feel the same, but the brand is actually a part that needs considerable attention.

(1). Look at the stepper motor: related to the engraving precision of the laser engraving machine, some manufacturers choose the imported stepper motor, some are the stepper motor of the joint venture factory, and some are the brand-name motor. II. Looking at the laser lens: related to the power of the laser engraving machine, the imported lens, the domestic lens, the domestic lens is divided into two types, which are produced by imported materials and produced by domestic materials. The price difference is very large, the effect and use. The life span is also very large, so pay attention to distinguish.

(2). Look at the laser tube: this is the heart of the laser engraving machine. Because the price of imported laser tubes is expensive, generally tens of thousands of yuan, so most domestic laser engraving machines use domestic laser tubes. The quality of the laser tube is uneven, the price gap is very large, and the service life of a good laser tube is generally about 3,000 hours. The poor laser tube has to look at it.

(3). Look at the quality of mechanical assembly: In order to reduce the cost, some manufacturers use a very thin iron sheet to make the machine casing. Users generally can't see it, but after a long time, the frame will be deformed, which affects the engraving of the laser engraving machine. The laser engraving machine should be framed, welded with high-quality steel, and made of high-quality cold-rolled steel to make the casing. When we buy the machine, we can see if the frame structure and the thickness and strength of the casing are used to find the quality. Good or bad.

The cost-effectiveness of the laser engraving machine, "the medium laser laser engraving machine is medium-priced and moderately priced. Many users hope that the laser engraving machine they purchase is "all-round", and everything can be done, omnipotent, which is actually No need at all. Pick the equipment that suits you is the best laser engraving machine.